How can we help you

for your next project?

Welcome to GalvaStrong a Mitsumi Housing Pvt. Ltd. enterprise providing full range of service in the sphere of LGSF structural design & Profile Supply worldwide.

The need for having a strong support system for erectors and contractors interested in LGSF technology is the need of hour. Through GalvaStrong we strive to be your pillar of support right from presentation to production. We can help you right from the first quote you present to your client to the production of LGSF profiles within the shortest turnaround time. Get in touch with us now and experience the brilliance of LGSF technology first hand.

Detailed Quotations & Marketing Help

We can help you right from marketing to sending the first quotation to your client.

Complete Support on Design & Details

We can help you with LGSF design irrespective of how complex it may be.

Quick Supply & Support on Erection

We can help you with quick supplies & complete help of erection of your project.

Light Gauge Steel Framing Sections can be used in multiple Industry verticals.

LGSF Steel profiles are parts of the Engineering Design

and made out of High Quality, Galvanized, High Tensile Steel.

Every aspect of structural stability is integrated in one system

with a proper load bearing technology.

Green Field Projects

LGSF Technology can be used for complete turn key

solutions right from foundation upwards.

Extentions Projects

LGSF is fastest and lightest for construction specific to

vertical extension in LGSF technology.

Modular Builds

LGSF is factory finished single structured units that can be shipped out lot wise as per demand.

Dry Walls

Modular dry walls are very easy in LGSF technology as the entire build process in completely dry and hassle-free.

Solar Stands

Solar modular mounting stands with high grade steel where there is no welding required is best with LGSF

Security Cabins

As LGSF technology offers one site build. Security cabins and modular toilets manufacturing with LGSF is best option.

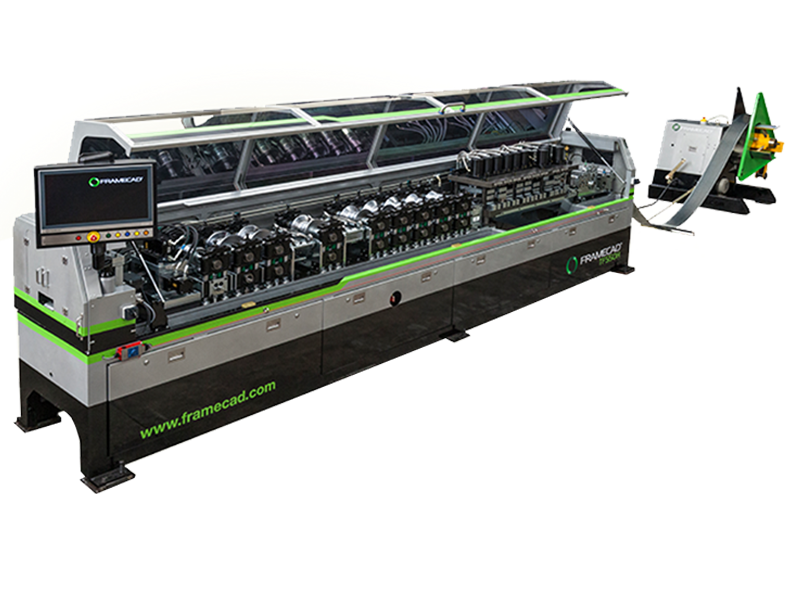

We work on latest LGSF hardware & software

4 High Speed Machines

15 Tons production capacity per day

(single shift)

F325iT (3 Machines)

Profile Width Material: 89 mm Std

Thickness:

0.55 - 1.2 mm (24 - 18 Guage)

Max Line Speed: 2880

Mtr/Hr

Production Speed: Joist - 300 M/Hr, Wall -

700 M/Hr

Design Software: FrameCad Structure &

FrameCad Detailer

TF550H (1 Machine)

Profile Width Material: 150 mm Std

Thickness:

0.95 - 2.0 mm (20 - 14 Guage)

Max Line Speed: 1350

Mtr/Hr

Production Speed: Joist - 300 M/Hr, Wall -

600 M/Hr

Design Software: FrameCad Structure &

FrameCad Detailer

Innovative and Sustainable LGSF Solutions. Contact us

Request A Quote

Complete control over products allows us to ensure our customers receive the best quality prices and service. We take great pride in everything that we do

We will get back to you within 24 hours, or call us +919820250100

Recent Articles

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, top news headlines.

Importers achieve cost savings through the First Sale rule!

The trade war currently ensuing between the US and several nations around the globe, most fiercely with China, shows no signs of the first set of tariffs levied against solar...

Read MoreCargo flow through better supply chain visibility, control.

Global provider connected products for consumers, and enterprises worldwide, supply chain control is everything, provide visibility and traceability needed for...

Read MoreImportance of specialized focus in Projects, Oil & Gas Logistics?

Our team provides highly skilled & experienced project managers who know the intricacies of this vertical and focus on providing innovative solutions in Oil & Gas sector...

Read More